PVC-O pipes are engineered for exceptional strength and durability. Through the orientation process, their molecular structure is rearranged, resulting in high tensile strength and resistance to impact.

PVC-O Pipes

PVC-O Pipes

Manufacturing

Manufacturing

Advantages

Advantages

Specifications

Specifications

Eco-Friendly

Eco-Friendly

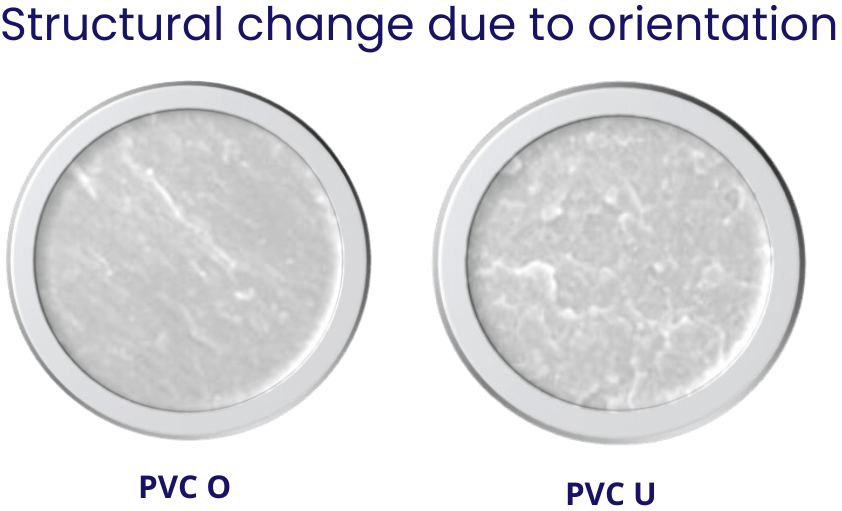

PVC-O (Oriented Polyvinyl Chloride) pipes are high-performance piping solutions produced through a process that aligns the molecular structure of the PVC material. This orientation enhances their strength, flexibility, and durability, making them ideal for applications requiring high pressure and resistance to environmental stress.

Total Dry System

Wide Range of Diameters

Integrated Socket System

Molecular Orientation

High Pressure Applications

Higher Strength and Durability

Energy Efficiency and Environmental Benefits

Improved Hydraulic Performance

Flexibility and Resistance to Pressure

Lightweight and Easy to Install

Cost-Effectiveness

Corrosion and Chemical Resistance

Potable water mains and distribution lines

Irrigation, water supply and recycled water schemes

Sewer effluent control and water purification

Conveyance of water to industrial plants

Conveyance of water underground

Use in desalination, treatment and recovery plant

Fire protection, urban water nets

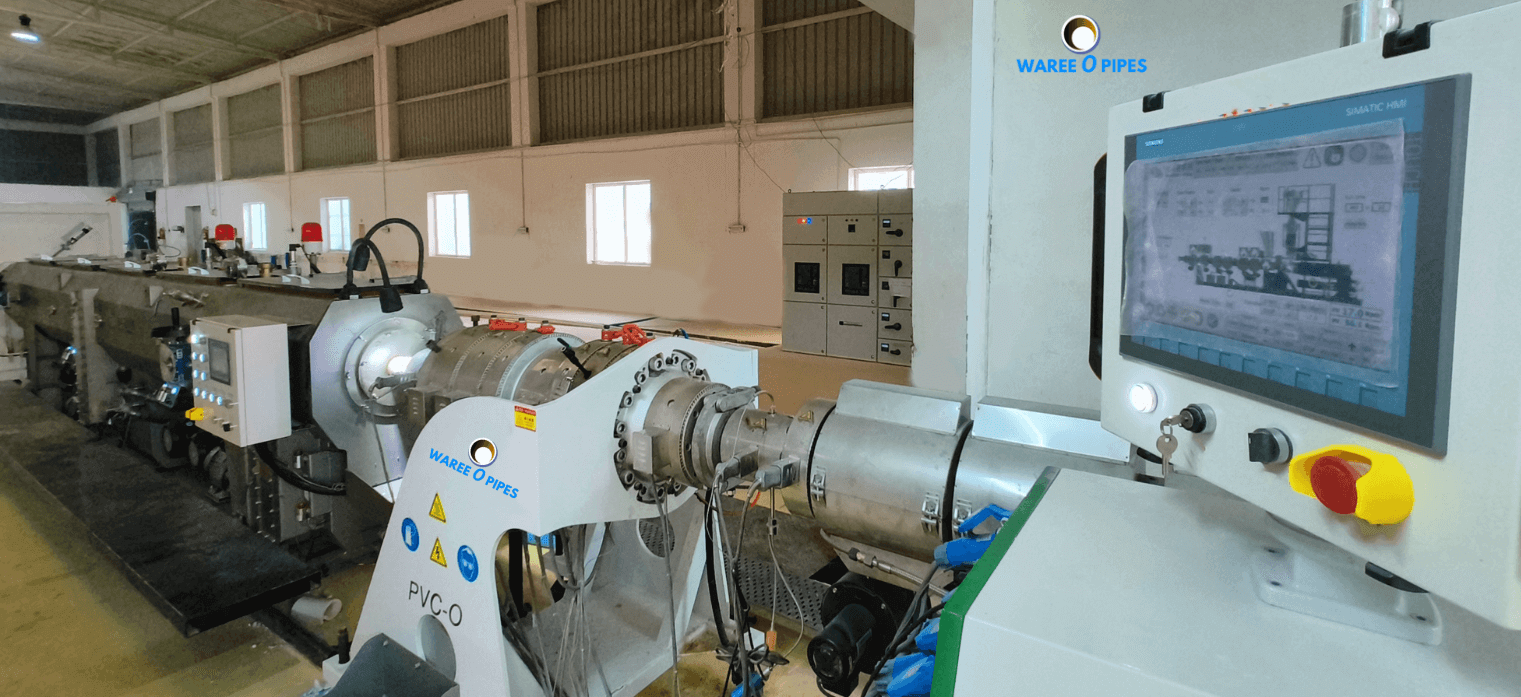

The manufacturing process for PVC-O (Oriented Polyvinyl Chloride) pipes involves several key steps:

Extrusion of U-PVC Pipe: The process begins with the extrusion of an unplasticized PVC (U-PVC) pipe. This involves blending PVC resin with additives and pigments, then feeding the mixture into a twin-screw extruder. The material is heated and forced through a die to form the pipe shape.

Heating and Softening: The extruded U-PVC pipe is then heated to a specific temperature range (85-100°C) to soften the material.

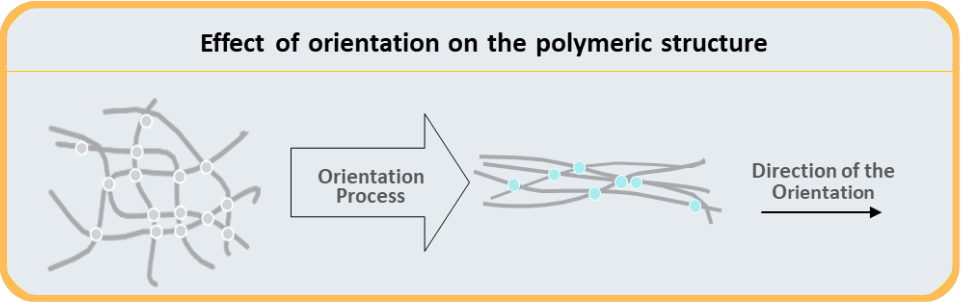

Molecular Orientation: At the softened state, the pipe undergoes a process of molecular orientation. This involves expanding the pipe's diameter using internal pressure or force. The expansion aligns the polymer molecules in a biaxial orientation, significantly enhancing the pipe's mechanical properties.

Cooling and Solidification: After achieving the desired orientation, the pipe is rapidly cooled to solidify the new molecular structure. This step is crucial to lock in the enhanced properties.

This process results in PVC-O pipes that are stronger, more durable, and have a greater internal diameter compared to standard PVC pipes, making them ideal for various pressure applications.

Maximum Flexibilty

PVC-O pipes are renowned for their exceptional flexibility, making them an ideal choice for a variety of applications. This flexibility allows the pipes to withstand bending and deformation without compromising their structural integrity, ensuring they can easily adapt to the contours of the installation site. Unlike rigid piping materials, PVC-O pipes can navigate around obstacles and adjust to shifts in the ground, reducing the risk of cracking and failure. Their lightweight nature further enhances ease of handling and installation, making them suitable for diverse environments, from urban infrastructure to agricultural irrigation systems. With PVC-O pipes, you can enjoy a reliable and versatile solution that promotes efficient water management while minimizing maintenance concerns.

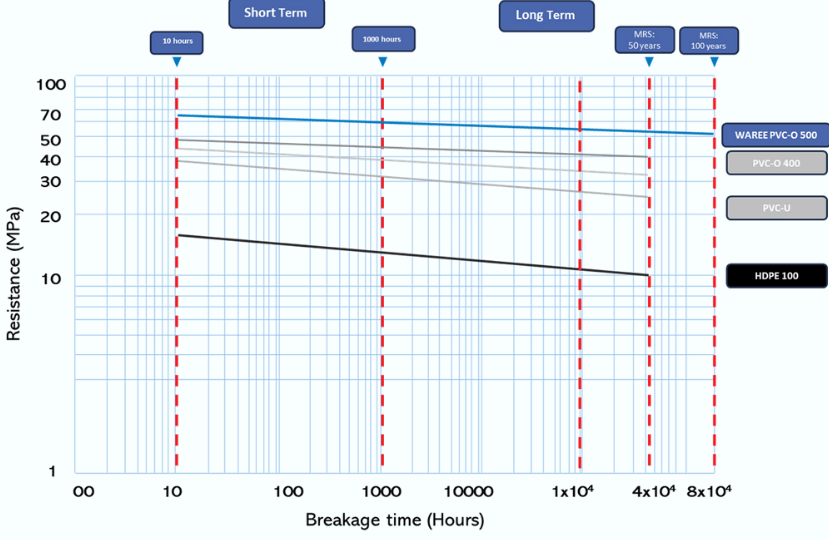

Excellent Short-term and Long-term Hydrostatic Resistance

PVC-O pipes offer outstanding short-term and long-term hydrostatic resistance, ensuring superior performance under pressure. Tested to handle internal pressures up to twice the nominal level (32 bars in PN16 pipes), they excel in withstanding high-stress conditions. Their resilience against pressure surges, such as water hammer and network malfunctions, further enhances their reliability in various applications. With low material creep behavior, PVC-O pipes maintain their integrity over time, contributing to their exceptional durability. Designed for an extended lifespan, these pipes can last up to 50 years at nominal pressure, making them a dependable and cost-effective choice for long-term infrastructure needs.

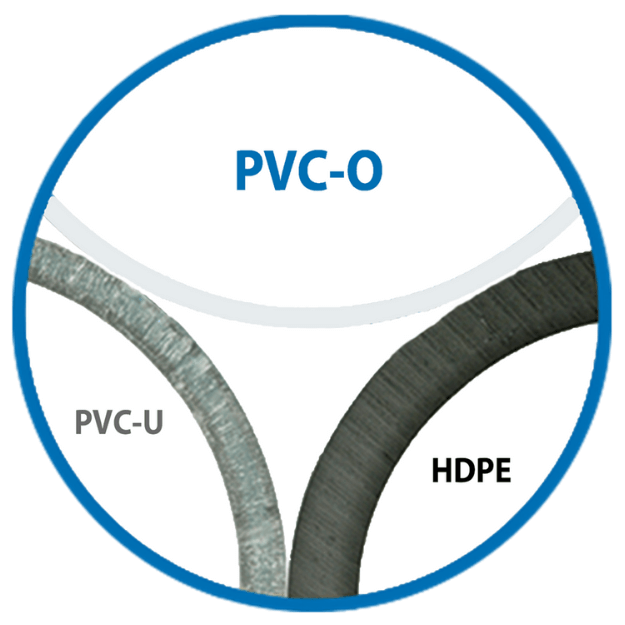

Increased Hydraulic Capacity

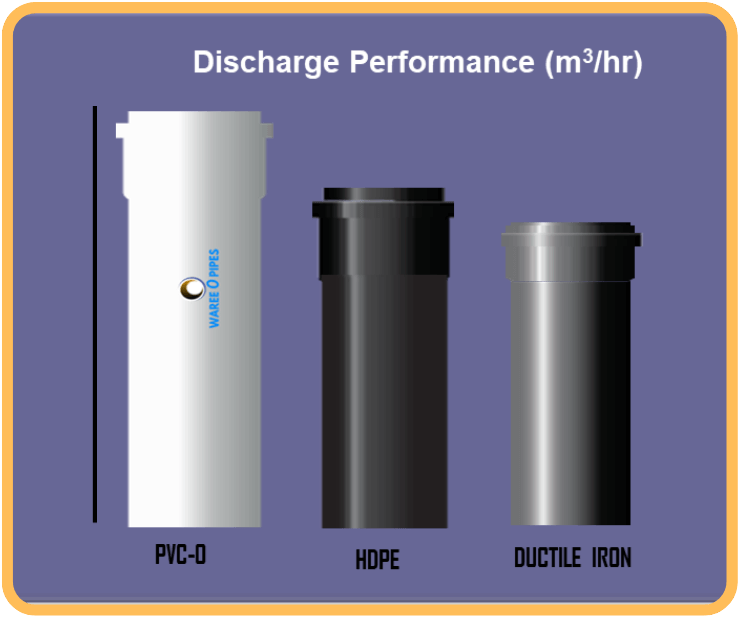

Waree PVC-O pipes redefine hydraulic efficiency through cutting-edge molecular orientation, achieving an impressive 50 MRS. This innovation enables a sleek, thinner pipe wall, unlocking a broader internal diameter and a more expansive flow section, allowing for unparalleled water conveyance. The ultra-smooth interior surface minimizes friction, drastically reducing load loss and preventing the buildup of deposits, ensuring a consistently smooth and efficient flow. Compared to conventional materials, Waree PVC-O pipes offer an extraordinary 15% to 40% increase in hydraulic capacity, making them the ultimate choice for high-performance systems where maximizing flow and efficiency is paramount.

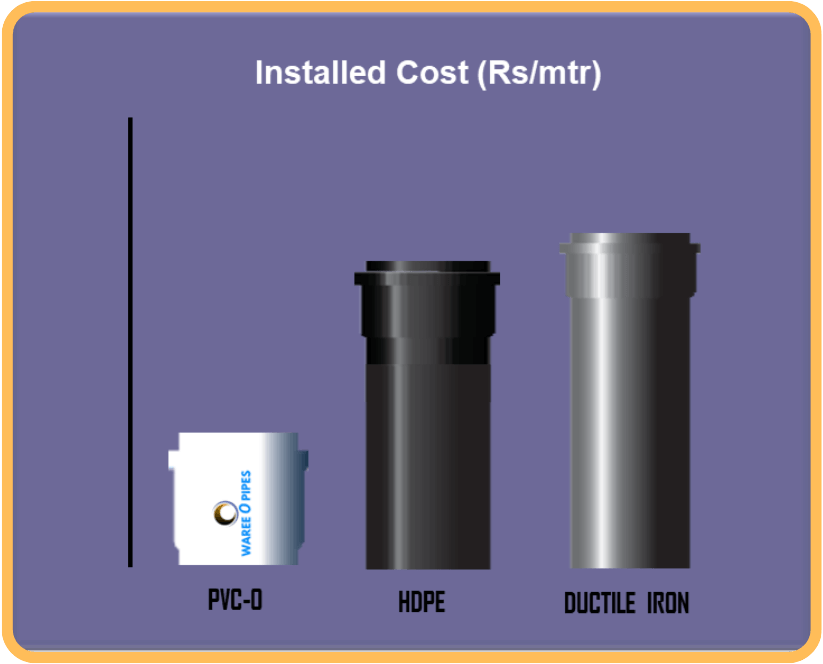

Lower Cost and Easier Installation

Waree PVC-O pipes offer a seamless blend of lightweight design and superior handling, making them far easier to manage than conventional piping materials. Their reduced weight means heavy lifting equipment is often unnecessary, while their exceptional flexibility and impact resistance simplify installation. With quick and easy connections, Waree PVC-O pipes ensure faster project completion, reducing both time and labor costs. Whether you're upgrading infrastructure or embarking on a new installation, these pipes deliver unmatched efficiency, combining lower installation expenses with long-term performance benefits that make them the smart, cost-effective solution for any project.

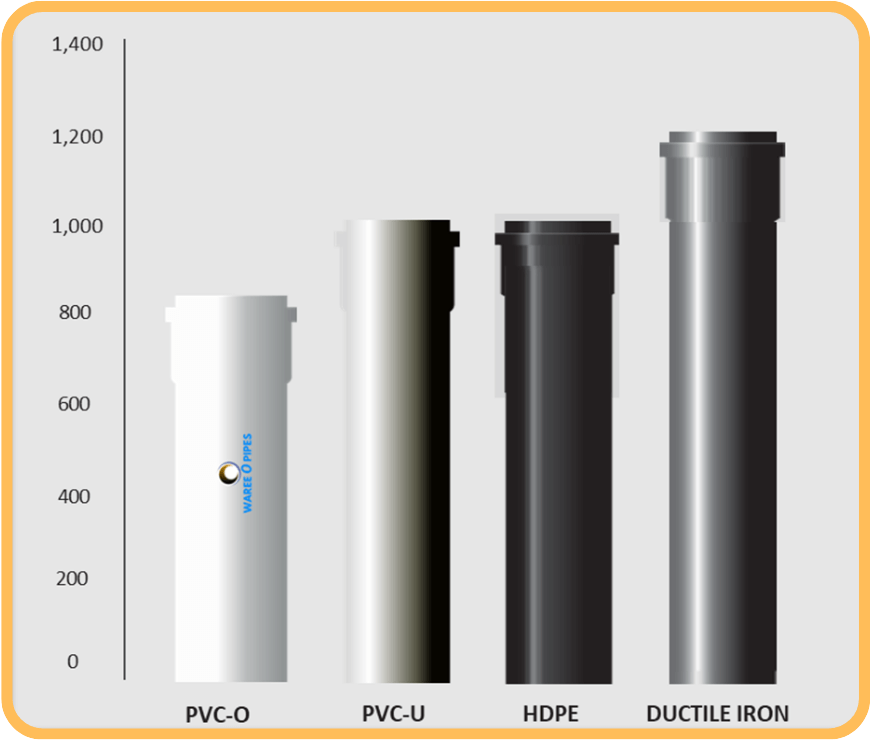

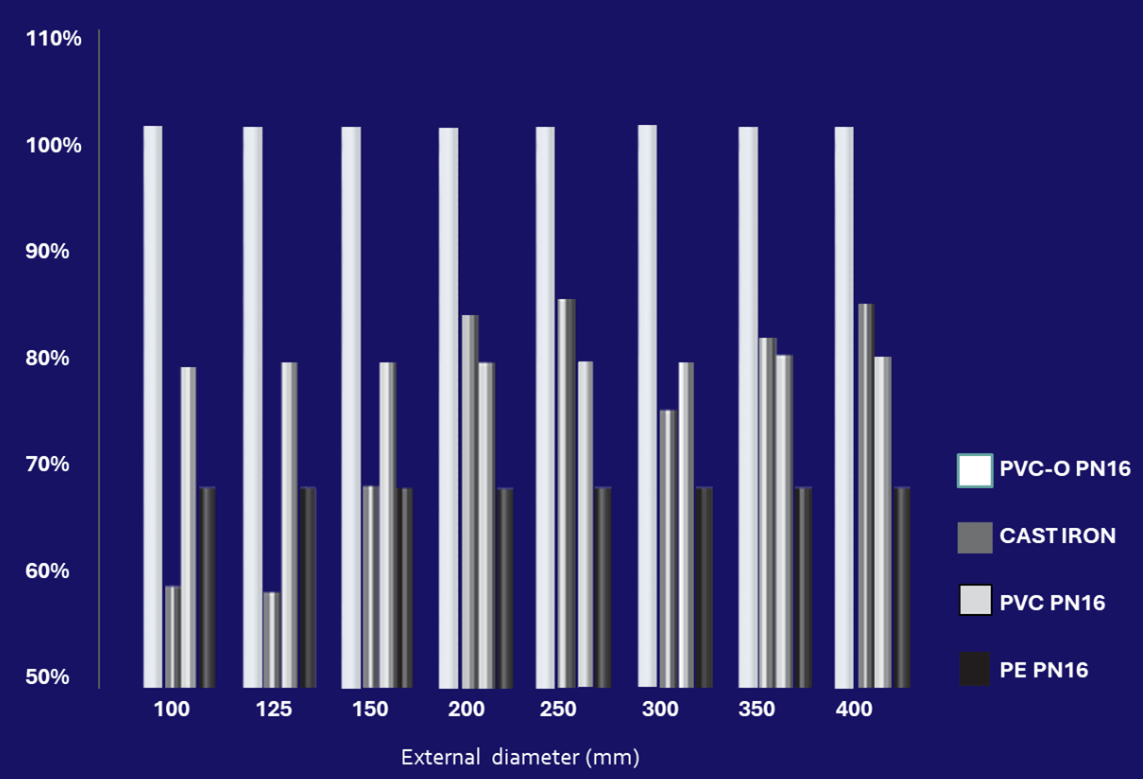

Reduced pumping cost (KWh)

Waree PVC-O pipes are engineered for exceptional pumping efficiency, outperforming traditional ductile iron and polyethylene (PE) pipes. Their ultra-smooth internal surface minimizes friction, significantly lowering energy consumption during fluid transport. This remarkable reduction in resistance translates to decreased kilowatt-hour (KWh) usage, resulting in substantial cost savings over time. By choosing Waree PVC-O pipes, you not only enhance operational efficiency but also contribute to a more sustainable and economically sound water management system, ensuring lower energy costs and a reduced environmental footprint.

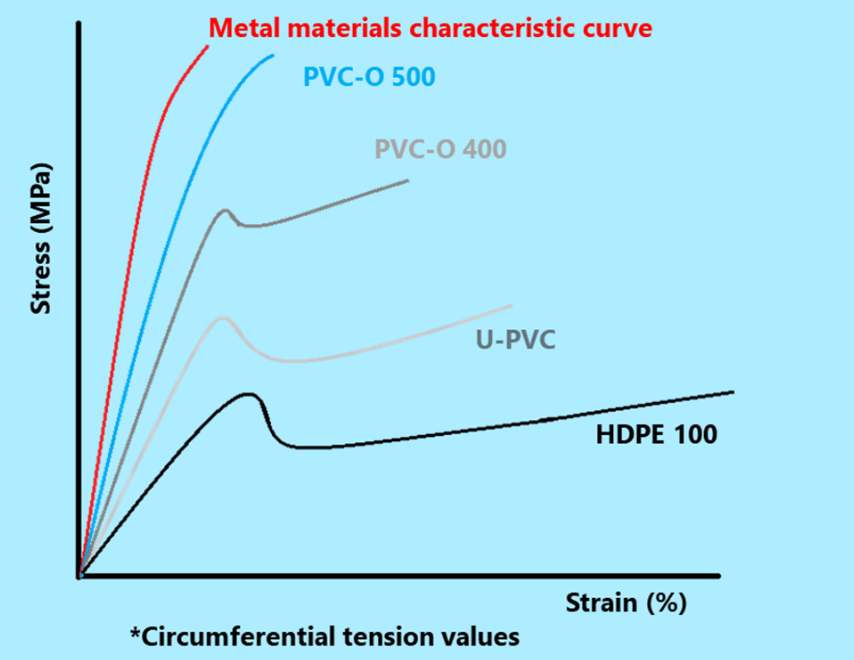

Mechanical Properties At It's Best

Waree PVC-O pipes exemplify mechanical properties at their finest, offering exceptional tensile strength that rivals that of metals. This remarkable stress-strain behavior underscores their robustness and durability, especially in higher PVC-O Class 500 pipes, where a complete transformation of mechanical properties is achieved compared to conventional PVC. Furthermore, these pipes demonstrate reduced creep, ensuring long-term hydrostatic resistance and stability in demanding applications. With outstanding fatigue resistance, PVC-O pipes maintain their performance over time, making them a reliable choice for infrastructure projects that require enduring strength and resilience. Invest in Waree PVC-O pipes for unparalleled durability and peace of mind in your piping solutions.

Stress Regression Line

The stress regression line for Waree PVC-O pipes serves as a pivotal tool in forecasting their long-term performance under sustained internal pressure. Derived from rigorous hydrostatic testing, this sophisticated analysis meticulously charts stress against time to failure on a logarithmic scale, offering invaluable insights into the pipe's lifespan and pressure endurance. By leveraging this data, engineers and stakeholders can confidently assess the durability and safety of these advanced piping solutions, ensuring that they not only meet but exceed the stringent standards required for reliable and enduring infrastructure. This robust predictive capability positions Waree PVC-O pipes as a benchmark of excellence in the industry, embodying a commitment to quality and performance that stands the test of time.

Hydraulic Design

The superiority of hydraulic design in PVC-O pipes over traditional PVC and HDPE pipes is underscored by the critical importance of accurately calculating hydraulic losses. This calculation is essential for designing both pressurized and gravity pipe systems, ensuring efficient water conveyance. Selection criteria for PVC-O pipes hinge on key factors such as internal pressure, flow volume, and flow speed, all of which influence system performance. Utilizing established calculation methodologies, such as the Hazen-Williams and Prandtl-Colebrook-White formulas, engineers can effectively assess friction losses and optimize the design. PVC-O pipes, with their ultra-smooth internal surfaces, offer significantly reduced friction losses, leading to enhanced flow efficiency and lower energy consumption. Furthermore, they are capable of withstanding higher internal pressures than their PVC and HDPE counterparts, making them ideal for more demanding applications. Their lightweight design also facilitates easier installation, ultimately positioning PVC-O pipes as the superior choice for reliable and efficient fluid conveyance.

Increased Hydraulic Capacity

In the realm of water piping networks, the ability to efficiently transport the maximum volume of water while minimizing energy consumption is paramount. Enter PVC-O pipes—engineered to excel in this vital aspect. With their innovative design featuring thinner walls than conventional plastic pipes, PVC-O pipes maximize internal diameter and flow section, facilitating superior hydraulic capacity. Their ultra-smooth surfaces further enhance flow efficiency, significantly reducing friction losses compared to traditional metal pipes. This unique combination not only allows for the seamless movement of water under pressure but also ensures lower energy requirements for pumping. By choosing PVC-O pipes, you’re investing in a cutting-edge solution that delivers both exceptional performance and cost savings, making them the optimal choice for modern water management systems.

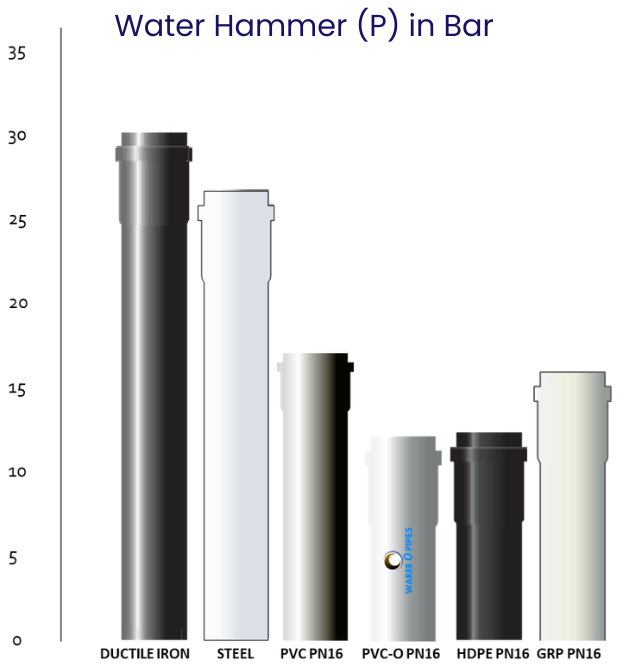

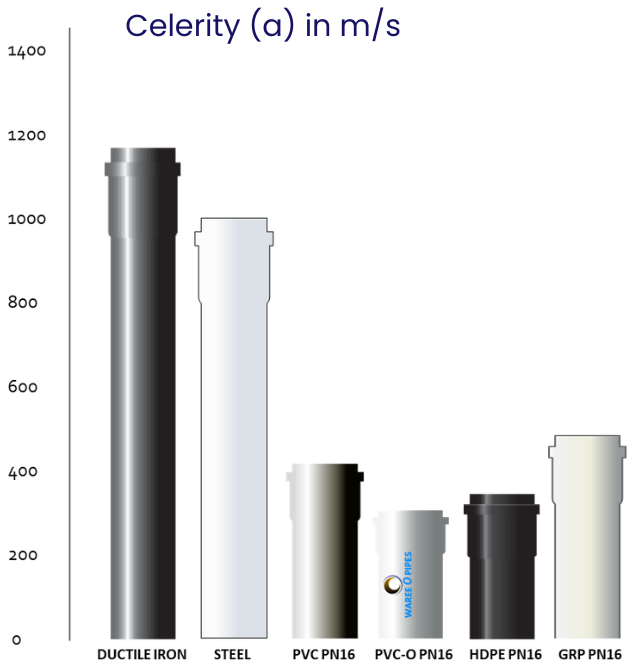

Water Hammer and Surge Velocity

PVC-O pipes effectively minimize water hammer and surge velocity due to their high flexibility and elasticity, which allows them to absorb pressure surges better than ductile iron or PE pipes, reducing the risk of pipe damage and ensuring smoother flow.

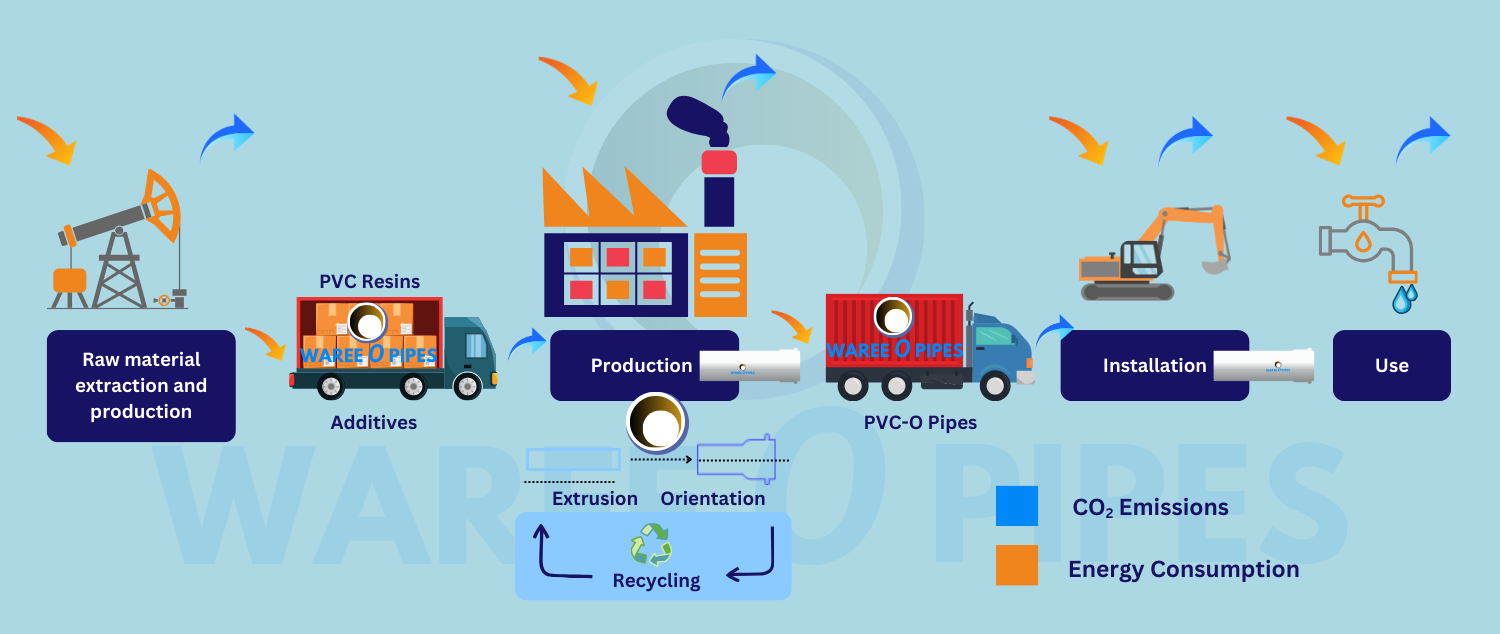

From raw material extraction to transportation, processing, and long-term use, Waree PVC-O pipes stand out as an environmentally conscious choice. They consume significantly less energy throughout their lifecycle, effectively minimizing their carbon footprint and promoting a greener environment.

Better Resource Efficiency in Every Pipe

Waree PVC-O pipes are crafted using only high-quality raw materials, ensuring durability and reliability. They are free from toxic substances, such as heavy metals, making them a safe option for various applications while aligning with sustainability goals.

Overall Performance

Lightweight and easy to handle, Waree PVC-O pipes offer distinct advantages over conventional materials. They excel in terms of cost, performance, and installation speed, providing a practical solution for modern piping needs.

Energy Efficiency

Designed to resist chemical attacks, these pipes prevent corrosion and significantly reduce the need for frequent replacements, enhancing their longevity. Their larger inner cross-sectional area increases hydraulic capacity, while the smooth inner surface minimizes fluid flow friction and pumping losses, leading to lower energy consumption. Choosing Waree PVC-O pipes means investing in a sustainable and efficient piping solution that meets the demands of today’s infrastructure.

Waree O Pipes implements rigorous quality control measures at every stage of production. This includes thorough inspections and testing to ensure each pipe meets high standards of performance and reliability.

Our products are validated by reputable industry standards organizations, ensuring compliance with international quality benchmarks and reinforcing our commitment to superior product quality.

We provide outstanding customer service through a dedicated team that is always ready to assist. Our support extends throughout the project lifecycle, ensuring timely and effective solutions to meet your needs.

Waree O Pipes is dedicated to investing in the latest technologies and research to drive innovation in our product offerings.

This investment allows us to continually enhance our products, ensuring they meet evolving market needs and deliver cutting-edge solutions for our customers.

Our team offers comprehensive technical assistance, from initial consultations to project completion, ensuring optimal use of our products and addressing any challenges that may arise.